Fungus Among Us [CASE STUDY]

A Macabre Tale of Moldy Meat and Chunky Cheese

Background

Food contamination can result from the accidental or deliberate addition of allergens, bacteria, mold, regulated chemicals, and foreign materials. A contaminant can be introduced at the time of manufacture and may not become apparent until the food is packaged or further processed. Undiscovered contamination can result in a financially burdensome recall for a company. A 2010 study estimated that a typical recall can cost a company $10MM on average, not including the damage done to a company’s reputation.1 According to a second report, there were 764 food recalls in 2016 with 44 being due to foreign material contamination like glass, metal, and plastic.2 When foreign material is found prior to product release, it is imperative that the material is identified and that the source or cause of the contamination be determined as quickly as possible.

Case Study 1

Consider the case of a beef jerky manufacturer in which a typically innocuous contaminant grew out of a packaging failure. Days after being warehoused at the manufacturer, a white deposit appeared on the product as shown in the image to the left. Was it mold or crystallized seasoning mixture used in the meat curing process? In a dried food product, a low water activity can help ensure that the product remains stable and that microbes won’t grow. Keeping the water activity low is ensured by storing products in hermetically sealed packages having both oxygen and moisture barriers. How can it be then that the substance appeared after the product was packaged?

Approach

When solving a problem like this it is best to start with simple tests, and then move to more complex ones if needed. Microbiological testing was performed to detect the presence of mold. The results came back negative. Results for elemental and organic compound analysis were not consistent with the matter arising from the seasoning mixture. Fortunately, the scientist’s toolbox not only contains microbiological and chemical tests, but also has advanced imaging techniques.

Images of the white material exhibited spherical structures contained in a web-like matrix.

Our lab turned to scanning electron microscopy (SEM) to gain insight.

SEM uses a beam of high-energy electrons to provide images with magnification up to 30,000X and spatial resolution on the order of 100 nm. Images of the white material (shown right) exhibited spherical structures contained in a web-like matrix.

Results

The features observed in the SEM images were characteristic of mold growth. The fact that the initial mold test came back negative indicates that the cells may not have been viable at the time of testing, but high-resolution images tell the full tale. Mold requires both oxygen and moisture to grow. After further investigation and discussions with the client, the problem was found to result from improperly manufactured packaging material – it lacked the proper moisture and oxygen barriers – and changes to the material were implemented.

__________

Case Study 2

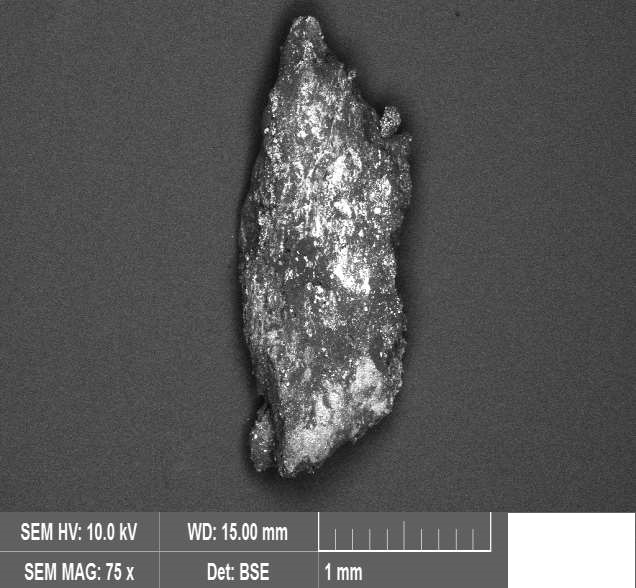

A manufacturer of dairy food products recently engaged our lab to investigate the appearance of tiny chunks (about 2 mm in length and smaller) of dark-colored material in a processed cheese. It was found to be embedded throughout the product (images follow). After a cursory visual examination of the material, it was hypothesized that it could be corroded metallic fragments or maybe a carbonized material. Tiny samples like these require sensitive testing techniques that can interrogate very small areas.

Approach

A typical approach to determining metals content in tiny samples would be to use Inductively Coupled Plasma - Mass Spectrometry (ICP-MS). This is an extremely sensitive elemental analysis technique with detection limits in the sub part-per-billion range. However, it is a destructive technique and the sample cannot be retained for future study. An alternative approach is to use a non-destructive technique that not only gives elemental content but also gives us information about the structure and form of the material. SEM combined with Energy Dispersive X-ray Analysis (EDXA) provided the imaging and elemental analysis information we needed without destroying the sample. SEM was described in Case 1. In EDXA a beam of high energy electrons impinge upon the sample resulting in the emission of photons in the X-ray region of the spectrum. The energies of the photons emitted are unique to the elements comprising the sample. Therefore, an energy spectrum can be used to obtain elemental content information. Combining SEM with EDXA allows one to collect a chemical profile of a sample with sub-micron resolution.

Results

A representative SEM image (left) and elemental composition report (right) are shown below for one of the chunks. The image didn’t provide enough information to determine if the material was metallic but the EDXA data did. The elemental composition was not consistent with that for a material composed primarily of metals and the metals that were observed are more than likely the result of contamination from the food sample. The compositional information for non-metals, combined with the image, did provide us with useful information. The relative proportions of carbon and oxygen and the morphology of the material observed are both consistent with filter media used in water filtration. This information allowed the client to investigate their inline filtration process.

Eurofins SF Analytical is renowned for successfully investigating the most challenging problems in food, beverages, and packaging; including product recall support, insurance and legal investigations. Please contact Mike Dziewatkoski, PhD at Michaeldziewatkoski@eurofinsus.com or call 262-754-5300 if you have a project inquiry or need to speak to a Eurofins Scientist about a problem you are experiencing.

- Report by Food Marketing Institute (FMI), the Grocery Manufacturers Association (GMA), and Deloitte; Recall Execution Effectiveness: Collaborative Approaches to Improving Consumer Safety and Confidence, 2010; p. 9

- Food Safety Magazine, A Look Back at 2016 Food Recalls, February 7, 2017, https://www.foodsafetymagazine.com/enewsletter/a-look-back-at-2016-food-recalls/